Enclosure: Franklin G. Smith’s Design for Improvement of the Printing Press, [ca. 23 November 1818]

Enclosure

Franklin G. Smith’s Design for Improvement of the Printing Press

[ca. 23 Nov. 1818]

It is taken for granted that paper of a proper width can be manufactured to any required length in a continuous sheet; as it is made in Delaware—perhaps in other parts of the U. States.

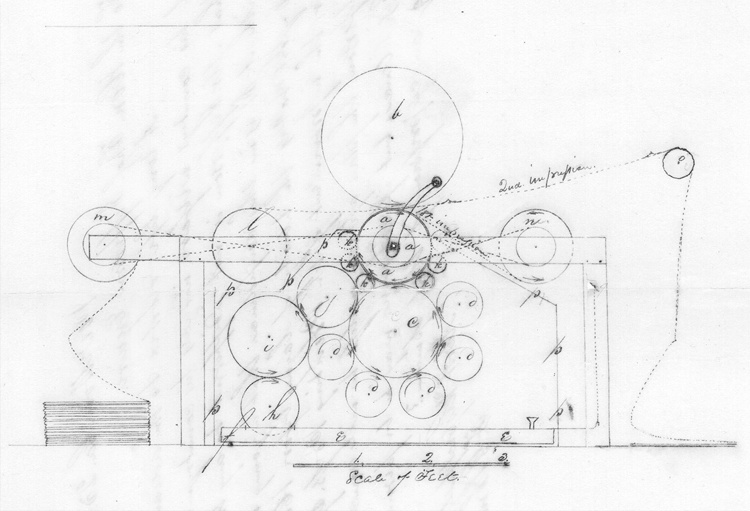

References to the figure.

a—is a round body 3 feet long, 1 foot in diameter to the surface of which the types are confined by means of a pressure at each end of the columns—they are not pressed sideways.

b.—is an other roller which produces the impression.

c. a roller that spreads the ink.

d.d. etc. rollers pressing on c. to lay the ink properly.

e. is the part containing the ink—stationary at the end f. and rises at the other end by turning g.

h. is a roller having 30 or 40 thin circular metalick plates projecting from its whole length which dip in the ink in1 e. and lay it on i. which communicates to j. whence it passes to c. & thence to the types.

k.k. etc. are rollers impinging on the types.—The paper is rolled on l. while in the station m.—At the first impression it is rolled on n.; but in the second passes over o.—All the rollers used in laying on the ink are enclosed by p.p. etc.

Types must be so cast that in setting them up they may represent a circle.

The press is put in motion by any convenient power.

MS (MiU-C: Thomas Jefferson Collection); entirely in Smith’s hand; undated; on same sheet as covering letter.

1. Manuscript: “in in.”

![University of Virginia Press [link will open in a new window] University of Virginia Press](/lib/media/rotunda-white-on-blue.png)