To George Washington from James Anderson (of Scotland), 15 September 1795–3 October 1795

From James Anderson (of Scotland)

Cotfield near Edin[burg]h

15th Septr[–3 Oct.] 1795

Honoured Sir

The respect I entertain for your character personally, may, perhaps, induce me to be guilty of an impropriety in thus addressing to you some remarks upon the easiest mode of constructing bridges of a large span, which I conceive may be of considerable utility in many parts of the united states of America, whose general prosperity I have been accustomed to believe, is at all times an object of your peculiar care—I hope the intention will be admitted as an apology with you, for any impropriety I may be guilty of on this occasion.

In what follows, I shall avoid entering into particular mathematical demonstrations; as a mere popular investigation, on the basis of common sense, will, I hope, be sufficient to illustrate the general principles upon which I shall reason, leaving mathematical precision to particular details when it is meant to be carried into actual practice.

The weight to be supported by every stone arch may be resolved into three distinct parts. Viz. 1st the materials of which the arch itself is composed, together with the parts necessarily connected with that arch. 2d The materials composing the road leading along the bridge—and, 3d the moveable load to be transported along the bridge, with its necessary appurtenances.

In the usual mode of constructing bridges the last particular, tho’ it is the sole purpose for which the bridge has been reared, bears a very small proportion of weight when compared with the other two parts. In most large bridges, if, E.G. the maximum moveable load were to be stated as one, the weight of the road will be perhaps an hundred, and that of all the other materials in many cases, an hundred thousand. From this view of the subject it appears that the strength of an arch is chiefly required for supporting the weight of the materials of which it is constructed; and, of course, it follows that if the weight of these materials can be diminished, the actual strength of the arch may be proportionally diminished without rendering the arch, in as far as the moveable load is concerned, weaker in the smallest degree. It is, therefore, an object of useful research to try if that weight can be practically diminished to any considerable degree, as thereby, not only may the actual strength of the arch be safely diminished without rendering it less fit for the purpose for which it is reared, but also the pressure upon the foundations be greatly lessened, and with it the total expence of the construction abated.

Where peirs, however, are to be placed in the course of a rapid river, the weight upon these peirs must be considerable, otherwise they would not be capable of resisting the force of the current—Hence—semicircular arches, when of a moderate size, where they are abutted by other arches of nearly the same dimensions, or by solid materials of equal weight, are found to be very strong, and stand firm for a great length of time—But where the arches are of a wide span, the great pressure of the materials accumulated between the arches of this form, is more than sufficient to counterbalance the direct weight of the materials that form the upper part of the circle, and the necessary equilibrium is destroyed and it tumbles down unless (1st) the crown of the arch be either much loaded by some fixed weight laid upon it—or 2d the pressure on the sides be lessened by forming cavities there of a proper size judiciously disposed—of & 3d by flattening the arch so as to make it suit the circumstances of the case. If—on the contrary, the arches be very small and flat, so as to be at, or even below a semicircle, the moveable load, may, at times, be such as to overcome the resistance upon the sides of the arch, and break it down—so that a cure, in this case, must be applied, of a tendency opposite to the former, that is to say, the materials that form the abuttment must either be made more weighty, or the arch be constructed of a greater height.

In attempting to make a flatted arch of great width of span, where the materials are of solid stone, two evils are to be dreaded. The first is, that it is impossible to join the stones which form the arch so closely to one another as to prevent them from being deranged and slipping out of their places, and falling down, unless these stones are made of a very great depth—or Secondly—if the stones be made of a sufficient length to obviate this evil, the pressure spread outwards at both ends, on a flat arch of large span will be so great as to render it impossible, in many cases, to get an abuttment sufficiently solid to overcome that resistance. On these accounts, flat stone arches of a very wide span, are found to be impracticable.

A stone arch, it is well known, consists of a series of wedges placed beside each other, which are preserved in their places by the power of gravity only. Did that gravity act perpetually in the direction of the Radius, tending to draw every stone with equal force towards the centre of the arch itself, the arch would be immoveably firm, considered in itself, and could only be destroyed by the materials of which they are composed, being crushed to pieces.

But as the power of gravity acts, not in the direction of the radius of the circle of the arch—but in that of the semidiameter of the earth, it is only the vertical stone in the arch that acts with equal force on both sides of the wedge, and in proportion as they recede from that vertex, the pressure upon each stone in the arch becomes gradually less as you recede from either side and of course they require to be retained in their places by some other power than the direct force of gravity acting on the stones themselves only. It is this complication of powers that renders the doctrine of arches a matter of so much difficulty.

If the arch be very flat—in other words if it be a very small portion of a circle of large diameter, the power of gravity alone will act with nearly the same force, and in the same manner, upon every stone in the arch, so that such an arch will be more simple, and will require fewer extraneous correctives to preserve it firm than Arches of any other form—All that is required in this case is, that the blocks of which it is constructed are of a sufficient depth and firmness to be able to surmount the inequalities that must arise from any imperfect joining in the pi[e]ces—and from the expansion or contraction arising from inequalities in temperature—That these blocks be sufficently firm in themselves as to resist any pressure to which they can be subjected—and that the abuttments be so solid, as to be perfectly capable of resisting the whole pressure that can ever be applied to them—and thus to prevent any spread at the ends of the segment of the circle.

These principles being admitted, it will be evident that if each block of which the arch consists, instead of being a solid stone were an empty box, the sides of which were so firm as not to admit of being crushed together by any weight that could be applied to it, the arch would be equally firm as if each block had been perfectly solid, but the weight would be greatly diminished.

In consequence of this diminution of weight, the lateral pressure on the abuttments of a flat arch would be propor[t]ionally abated—consequently the width of the span of the arch may be augmented in proportion to the diminution of the weight of each of these wedges.

If a weight be laid upon the sides of an empty box made of wood or other elastic materials, it will be made to yield, and be pressed out of its proper shape with little difficulty—But if a rod of iron were run across that box so as to apply each end against the sides to which the pressure was applied, the sides of the box would thus be prevented from yielding. And if these sides were only at a very small distance from each other, a very small rod would enable it to bear an inconceveable degree of pressure without giving way.

The same effect will be produced where the sides of the box are at a considerable distance from each other—if the rod, by any contrivance, can be prevented from bending, by having supports placed on every side at small distances from each other along its whole length. All this is so obvious as to stand in need of no particular illustration.

It is upon these principles the improvements I am about to suggest in regard to the construction of bridges are grounded—and I trust that the means for effecting these ends will be found to be so simple, and so easy to execute, as to render it extremely practicable to carry them into effect.

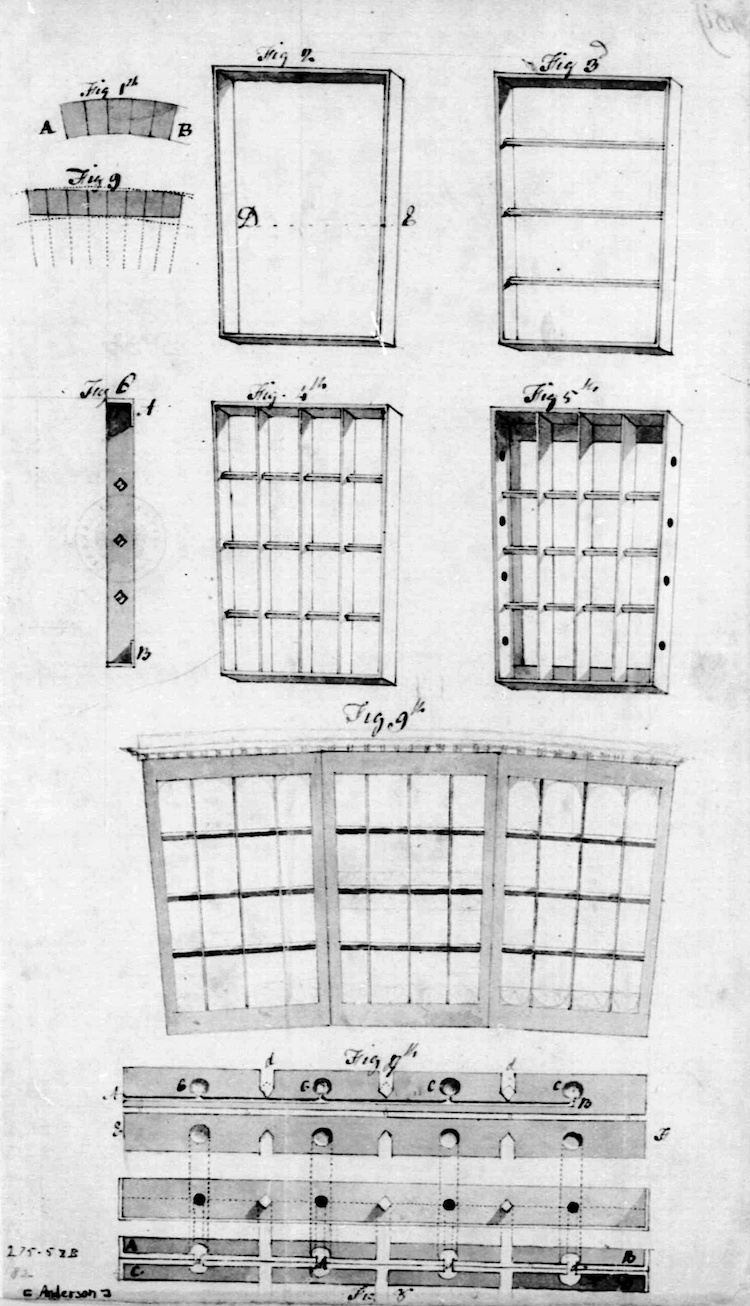

Fig. 6. James Anderson’s sketch depicting components of an iron bridge. (Library of Congress)

Let A B Fig. 1st represent a small segment of an arch,1 consisting of solid stones placed in the usual way. It is plain, that if these stones be long enough, and the abuttments firm this arch cannot give way.

Let D E Fig. 2d represent one of those blocks on a larger scale, which instead of being solid stone, consists of four boards of wood, or other elastic materials being hollow in the middle. Its weight would be greatly diminished; but its strength also would be mucch abated.

If the pressure were only from D to E the strength would be greatly augmented with very little addition to its weight by having one, two, three or more bars of iron put across it, as in fig. 3d.

But, as these bar’s, on account of their length, would be liable to be bent, it would be of much utility to have these bars stiffened by means of girders running perpendicular to them, as in Fig. 4th.

It is a known principle in mechanics, that where a board of wood or other matter whose continuity of parts is uniform, be intended to resist a force applied to bend it, the resistance it will make is not in proportion to the quantity of matter it contains, but varies with its relative proportions. If the board were one inch thick, and 12 inches deep, and if it were capable of bearing a weight of 12 when the pressure was applied perpendicular to the thin way of the board, its resistance would be 144 if the pressure were applied perpendicular to the depth of the board—If the board were 24 inches deep, the resistance would be equal in the thin way to 24—and in the deep way 576—and so on—the power of resistance increasing in the one case in an arithmetical, and in the other in a geometrical ratio.

To apply this principle practically in the present case is very easy. To prevent the bars which stretch from side to side of the frame from bending it is necessary they should be secured at short distances by means of girders. If these girders be made of flat and thin pieces of iron, with the bars running perpendicularly across them, these girders will, in that position, act with a force much greater than if the same quantity of material were employed in a square form. Thus is great strength obtained with little weight; and no waste of material.

I propose then, that each block intended to compose an arch should be made of cast iron on the principles above explained, and into form represented in Fig. 5—which will I hope be so plain merely on inspection as to require few words to illustrate it. I did intend to have sent a small model of three of these blocks joined together but, on account of the difficulty of sending them to London, and the little use for them after the drawings were made I thought it quite unnecessary to forward them. You will please to observe that for the purpose of stiffening the bottom and top edges—a plate of iron is proposed to be cast at right angles with them—only on one side—as is seen in Fig. 5th—and a narrower plate on each side as is also seen in Fig. 5 and again in front at Fig. 7th—(A section of the top and bottom plates— with these perpendicular plates joined to them is seen at A & B. fig. 6th which will, I hope be sufficiently explicit.)

These blocks could be made, by a skilful founder, even when of a very large size, and with the girders very thin, all at one jett: but less skilful artists would find some difficulty in doing this—so that, where only such imperfect artists can be found, it might be necessary to have the girders first cast by themselves, and the strengthning bars afterwards made to flow through holes left in these girders for that purpose when the frame and strengthening bars were afterwards cast. Even in this imperfect way of working, the parts might be quite firmly united together because of the well known property of iron expanding in the act of pressure from fluid to a solid state—This junction will be rendered still more secure, by leaving a small bridge across each hole—as is represented in Fig. 6th which exhibits a side view of one of those girders. One other advantage that might be derived from casting the girders separately would be that of allowing these girders to be cast—not solid—but in hexagonal bars, with openings between like a section of a honeycomb by which means their weight might be still farther diminished with a very small abatement of strengt⟨h.⟩ I hope to be pardoned for mentioning these operati[on]al minutie, which if they had been omitted might have been urged as objections—I have not thought it necessary to tire you by showing how the horizontal & perpendicular board, at top and bottom may be compactly connected with these in casting—because the same principle applies to both.

The next particular that requires to be specified in constructing this kind of bridge, is the mode of joining these blocks to one another so as to keep them perfectly true in their places, and render the whole as firm nearly as if it were made of one piece only—It is in regard to this particular only that I lay claim to any degree of originality—and I am happy to think that this will be found to be so easy in execution, and so perfect in its kind, as to be applicable to an immense variety of cases in the use of cast iron, which will render this manufacture, in time, of the most extensive utility for the common purposes in human life—I look forward with much satisfaction to the uses which mankind will derive from it—of which we have scarcely as yet obtained a very feeble glimmering.

The first iron bridge that was erected in Europe, as far as I know, was in Britain, and, as in most new attempts, it was constructed on principles so very erroneous, as to be, in the present day not deserving a serious investigation. Since that time attempts have been made to build several iron bridges on the principles of a stone arch, in which various devices have been adopted to diminish the weight of the blocks, all of them, that have come to my knowledge, differing very considerable from that above developed. The bridge now erecting over the river wear at Sunderland is the most magnificent of these that I have heard of. It is to consist of One arch of 240 feet span. I have doubts of the final completion of that bridge, not so much on account of the form of the blocks (which are however objectionable tho’ the quantity of metal in them is so much greater than would have been necessary, as may still give them a sufficient degree of firmness) as from the imperfect mode adopted for connecting these blocks, and firming the ribs laterally, of which more anon.

The blocks of which the sunderland arch are to consist are to be joined together by means of three bars of wrought iron, one at the upper, one at the under edge and one in the middle part on each side of the blocks, running the whole length of the arch. These bars of iron are connected together by means of bolts passing through holes in them and in the cast iron blocks made for that purpose and firmly screwed home. I will not take up your time by stating objections to this mode of joining the blocks, as these are sufficiently obvious.

Instead of this, I propose that holes be made in the flatted sides of each block, as are seen in fig. 5th the holes in all the blocks corresponding exactly with each other, so that when one block is placed by the edge of another true upon the coomb (the wooden frame that supports the arch) as is usual in building arches there shall be holes clear through both the edges of the adjoining blocks—when they are in this position, let a mold, of the same nature with that for casting musket bullets, having a groove running along its whole length upon one side, and communicating with circular cavities form⟨ed⟩ in it be provided, as at Fig. 7th in which A B represents the groove running from top to bottom, and c c c c the circular cavities communicating with it. This mold (which is here drawn on a scale twice the size of the other parts[)], is to be applied to the inner edge of one of the sides of the block so that the circular cavities shall be placed directly above the perforation in the sides of the block—and of course, the open places d d d embrace the square bars. On the opposite side of the other block, now closely connected with the former is placed another mold E F—corresponding with the former in all respects, with the omission only of the perpendicular groove. When these molds are applied close on either side of the two corresponding blocks, they are firmly screwed together by means of cramps similar in kind to those usually employed by joiners for driving home the joints of chairs &c.—While they are in this position—let some melted iron be poured down the groove at A. It will then flow to the bottom of B. and entering into the cavity c it will flow through the hole into the corresponding cavity in the other mold, so as to fill the whole: and so on through all the other cavities till it reaches the top. After the metal has become solid, the molds may be then removed, and the two edges of each block will then be connected together by means of Strong iron bolts with double heads, as is seen at fig. 8—in which A B represents an inside view of one of the thin plates at the edge of the block—and C D the same of another block—with a section of the side plate of each block connected by the double headed bolts just described d d d d. All this will be sufficiently plain by inspecting the figure.

By this mode of joining, which is the least expensive that can be conceived the two blocks will be connected together more firmly than by any other mode that could be devised. For, as the double headed bolts are made to fill the cavity while red, hot they must of necessity contract in length as the heat abates, and of course they cannot fail to draw the two blocks more powerfully together even than the cramps themselves could effect—I have here only to remark a small error in the drawing of this part that ought to be adverted to—Instead of one bolt on the outside of the bar both above and below, there ought to have been two, the outermost of which ought to be very near the extremity of both ends. There are several other little niceties that would require to be adverted to in practice; particularly as to the application of the molds so as to prevent them from being deranged by the expansion in the act of becoming solid—which I have not thought necessary to detail.

Three of the blocks are represented as standing in their places thus connected together in Fig 9th. On the top of them is represented a slight sketch of a cornice in wood, which might be made to run along the whole, and would prove not only ornamental, but useful also. I have bestowed no pains on decoration here, having confined myself to the most simple forms for the sake of illustration only—But it is obvious, that without incurring any additional expence these structures might be decorated at pleasure merely by varying the form of the upper and lower facings—But on this head it is unnecessary to enlarge.

The several blocks of which the arch consists being, in the manner above described, as closely jammed together without wieght, as stones can ever be by the greatest pressure of their natural gravity, and much more firmly connected together than stones can possibly be in any situation, the whole of a rib of this kind may be considered as equally compact nearly as if it consisted of one piece only without any joinings whatever.

An arch, upon these principles, can be rendered of much greater absolute strength than even a stone arch—because the blocks are not only firmer of themselves, but can, without difficulty, be made of much greater depth than it is practicable to make them of stone—In few places stones can be had that admit of being dressed into the true shape for an arch that exceed three or four feet in depth—It would however, be an easy matter to cast blocks of iron, upon the principle above developed, Six or even eight feet deep if necessary—But when the diminution of weight is adverted to, it will appear evident that a block of iron, thus employed, of two feet in depth, could bear a greater passive load, than a stone arch could do were the stones even of six feet deep each—But if the iron arch be made of blocks of six feet deep, the proportional strength of it must be wonderfully augmented.

From this consideration, it would be a foolish enterprise to make a bridge of iron consisting of blocks placed close to each other over its whole extent, as in stone arches. A few parallel ribs of iron placed some distance from each other, so connected together as to support the road above them, is all that can be wanted for the ordinary purposes of life, And it becomes a question how many of these ribs there ought to be, and in what manner they should be connected so as to render the bridge firm & durable.

In respect of the number of ribs—considering the strength that can be given to them at pleasure, I have no difficulty in saying, that for the purposes of strength alone, more than two ribs can never be necessary—Conveniency, may, in some situations make it eligible to give them three ribs—But when the road is to be supported by transverse beams of wood (which is in all cases the cheapest, and for the most part the best mode of doing it) more than three ribs can scarcely ever be required.

I am afraid it would prove tiresome to you were I to enter into details of the best mode of constructing the wooden parts of these bridges—and it would require still more complicated details to illustrate the manner in which the ribs might be best connected together, so as to enable the structure to bear a lateral pressure from wind or other causes. This is a peculiarity in the art of bridge building, which, as being unnecessary to advert to in bridges of the construction that has hitherto been most common has been almost entirely overlooked—but which must, upon the plan here recommended be peculiarly adverted to. Should the principles above explained give such satisfaction, as to induce the united states seriously to think of erecting any important work upon that plan, I shall be ready to give every explanation that may be wanted. At present I shall trespass no farther upon your patience than merely to notice a few of the purposes that these kind of arches seem to be more peculiarly adapted to—and to obviate a few objections.

First—On account of the very small weight of materials that are thus required—a bridge of a very large span may be made, so as to avoid the necessity of having many piers in the water. A rib of 500 feet span could thus be made that would be strong enough to support any load that could ever have occasion to pass along it, that should weigh only from 30 to 40 ton of iron—of course the resistance necessary to prevent the spread outward at each end of a flat arch would be so small as to be easily obtained.

2d as a corollory from the above, the arch may be made, in all cases as flat as circumstances may render necessary—where an aqueduct bridge is required, and where, of course, it must be entirely level, there would be no other difficulty than that which arises from the necessity of making, in this case, a distinct mold for each two blocks of the same rib—there being no other obstruction to the making a horizontal arch (excuse the seemingly improper expression) as marked at Fig. 9th but that alone of preventing the outward spread at the abuttments.

3d The expence of erecting bridges on this plan would be greatly diminished, in those of a wide span especially—For, if the omission of, the otherwise neccessary piers be taken into the account, it will be no exaggeration to say that a bridge could be thus erected, in most cases, for a less sum than must have been expended on the meer carriage of the materials only for a stone bridge of equal length.

4th But it must ever be adverted to, that however strong a bridge may be thus made, considered in respect to perpendicular pressure, it can never be made so strong as a solid stone arch for resisting any lateral pressure, owing to the smaller weight of the whole structure—On this account, iron bridges thrown over navigable rivers, ought in general to be raised so high above the water as to allow vessels to pass without striking their masts, or at least, so high as to admit of being touched, in case of unavoidable accidents, by the smaller part of the masts only, which will give way before the structure can be deranged.

I might here also show in what manner houses could be erected of cast iron, and firmly connected in all their parts, and more elegantly finished both externally and internally, at an expence greatly below what they could be reared for of any other materials, and possessing other advantages of which they could not otherwise be susceptible. But I have already transgressed too much upon your time to enter upon that field. I have no other apology to make for this presumption but that which I have already offered—I live now a quiet and retired life, out of which I never wish to emerge—My enquiries are directed solely towards objects of utility to mankind, without any prospect of emolument to my self, and I have no other wish than to render the fruits of these enquiries as generally useful as possible. This wish confers a tranquillity on the decline of life which nothing else, I think, could do—If I mistake not you also take pleasure in pursuits of the same kind—May Heaven long enable you to continue them, and grant that your beneficent exertions may be ever crowned with success.2 I have the honour to be, with the most cordial esteem Honoured sir, Your much obliged, and Most obedt Hu[mbl]e Servt

Jas Anderson

London—Octr 3d

P.S. At the moment when this letter was ready to be sent off, I have just learnt that a new iron Bridge of 90 feet span which had been just compleated in Worcestershire is fallen down3— From what I have been able to learn of the principles on which this bridge was constructed (nearly the same with those of the original bridge at Coalbrookdale in Shropshire) I am less surprised at its falling, than at its having stood one moment after the supports were removed—so that I consider this accident of no consequence as an objection to iron bridges—It will however, be eventually of much use, as it will induce mankind to enquire a little more particularly than they have hitherto done, into the principles on which these bridges ought to be constructed.

ALS, DLC:GW.

1. For the sketches discussed in this letter, see Figure 6.

2. GW responded to this letter on 15 Feb. 1796.

3. The Whitehall Evening Post (London) of 1–3 Oct. reported that on 26 Sept. “the new iron bridge over the river Team, at Stamford, in Worcestershire, suddenly gave way, completely across the centre of the arch, and the whole of this elegant structure was instantly immersed in the flood!” The bridge was “passable,” almost ready for use, “but no carriage had yet passed over it. … The span of this bridge was about ninety feet: and the misfortune is generally imputed to the slightness of the iron-work, which was several tons lighter than the celebrated bridge at Coalbrook Dale. The mason work remains uninjured.”

![University of Virginia Press [link will open in a new window] University of Virginia Press](/lib/media/rotunda-white-on-blue.png)