Charles Willson Peale to Thomas Jefferson, 28 December 1813

From Charles Willson Peale

Belfield December 28th 1813.

Dear Sir

It is long indeed since1 I have intended to answer your letter of April 17., at first I wished to finish my Corn-fields according to your directions, and after that I wanted to hear the observations of my Neighbours—and I must say that every one with whom I have conversed acknowledge the improvment of making hilly ground equally advantagous as level fields. your letter came to me at the proper Moment for me to make the experiment on some of my hills, though none of my land is very hilly—even my Garden which is on the side of a hill has received advantage by your lesson—about 3 years past I experienced the disadvantage of having furrows down hill, the land was considerably washed & the grain suffered by the floods of Rain. I was led to plow in that direction by the oppinion of Mr Job Roberts (author of the Penna farmer) who directed that Corn would be best planted North & South, by which he said the Sun would have greater access to the bottom of the Corn—The loss I sustained in the field above alluded to, brought me to think on what he had said, when I was satisfied that Corn planted East & west would have a better chance of the benefits of the Sun, as the Sun would shine between the rows both in the morning and evening, and the meridian Sun would not be intirely lost in our longest days.2

I am inclined to believe that my Corn has been improvd by this culture, for I have a greater quantity this year than on former years, if I was to make the estimate of the proportion of ars planted each year, I could thus speak with greater certainty, but this one thing speaks to the purpose, I bought a wire-corn-sive of Mr Nathan Sellers, and I think he has been careful to make such sives of the best size—on tryal of this Sieve I find my Corn will not pass through it, except the small grains taken from the ends of the Cobs—Perhaps the kind of Corn which I have choosen to plant may be generally of larger grain than the Gourd seed-corn—my Corn is the hard yellow corn—I have not yet tryed my Corn which I have grown3 for Homony, which is white and flinty.

My attention has been engaged in making fences, and as far as yet that I have made tryal, it appears very plain that Hedges & ditches is not only the best kind of fence, but also, that they can be made nearly as cheap as the Post & rail fence, and by making a good ditch that they are defence against any kind of Cattle in the first year—It has been said that we loose some ground by the ditch, if that is a small loss, the obtaining a permanant fence makes up fully for that loss. Some Gentlemen have told me that I could not afford to make such fences, that in Europe where labour is so much cheaper, that they complain of the expence—It appears to strike me that the people in Europe do not manage the business properly, probably they depend on the Spade in making their ditches—My Method is to use my strongest plow, drawn by a pr of oxen with two horses to brake up the Soil, this is soon thrown up on the bank with shovels, and when the ditch is deepened, lastly we use a Single Horse plow, by this method, much labour is saved—but if the land is stoney, in such places we cannot have the full benefit of the plow. That many of my country-men have not succeeded with their thorns is I believe owing to their neglect of weeding & dressing in the first 2 or 3 years after planting them—This is only the 3d year since I began, and some of my Thorns will be in 2 or 3 years more a complete fence with small ditches. It appears to me that the New Castle Thorn will make a better fence than the Virginia Thorn, as the spines are strong and large—and the Thorn is more bushy, That of Virginia grows fast, but spiring, to take benifit from its quicker groath we should cut it more freequently, I believe it4 must be trimed twice in the year, early in the spring and again in midsummer. Thorn fences are indispensably necessary in the Vicinity of large Manufactories; to keep the people belonging to those factories from trespassing on our fields, in crossing our farms by every direction they are permited to go5—The Neighbourhood of Germantown promises to become the seat of much Manufactories—The breeding of Sheep seems to engross much of the intentions of merchantile men as well as farmers, it appears to me as something of mania, at least the profit they speak of6 must be exagerated—My Thorn fences must get their necessary groath before I shall attemp keeping any sheep—an increase of Manufatories no Doubt will call for much wool, and we are going so fast into making cloath as well as Cotton goods that should the war continue any length of time it will probably induce monied men to employ their funds in establishg manufatories—My two youngest Boys I have put in a Manufactory of machine making, the elder of them has considerable mechanic talents, He will in one year become master of all that is necessary to enable him to undertake that business, yet my view in puting Him7 into such a manufactory was that he might qualify himself to undertake the management of the Cotton business, and knowing how to make the machines, will give an advantage of knowledge to keep his machines8 in the best order.

My labour on the farm is not so active as you may imagine, occasionally I give my aid, but a great part of my time is imployed in making Machinery at my Mill, and it being a new work to me, has given me more labour than necessary, but accomplishing the several objects undertaken gives me content. I made a Thrashing Machine from a description given me by a mill-wright, It is the Scotch invention; a Drum with dashers to strike off the grain that is carried forward between fluted rollers, The sheaves carried to the Rollers in the manner of the carding machine i.e. a cloth mooving on two rollers—The whole of the moovment of this machine is perform’d by Straps—It was some time before I could determine the best proportion of moovements—at present I have make the Drum which has 6 dashers to give about 1000 strokes in a minute, the feeders give about ¾ Inch of length of the grain to each stroke. The Straw is considerably broken—I have seen another method, a Patent machine. It is also with a Drum, but with its surface studed with pins, the Grain passes between the Drum and an Iron bar, this bar is mooved by screws to give it a greater or less distance from the Drum—This Machine does not brake the Straw; it comes out flattened. I am told that it thrashes fast, for a long time I had my doubts whether I should not get this kind of Machine, but from what I have heard and seen of the Machine, I judge that the person who feeds it must be very careful in not feeding too fast, or the Machine would be liable to be stoped by choaking and thus injure the machinery—I cannot be a proper judge as I have not yet seen its opperation.9

I have a Machine for getting out clover seed, the invention of Jonathan Roberts, who paid for a patent many years past, but would not let any person see this Machine, not even his children, after his death I bought his Machine, It is on the principle of a Coffee mill; the first he made was a conic cylinder whether he found it required more power than his Horse could give to work it, or whether the heads did not pass through it sufficiently quick, I have not been able to learn, but he substituted a perpendicular cylinder with the same kind of Gores as in the other, this Cylinder considerably smaller in the Diameter than his conic cylinder. This Machine seems to turn out the husk well broken—There was no sieves or fans, these I have added, and hope I shall get the seed pretty clean, which I find is not easily done, even with the use of the Common wheat Fan & screenes.10

I have attempted to make a Machine to take off the heads of Clover instead of moowing to get the seed—low Truck-wheels;  the points are plates of Steel, they take off the heads with ease, but I found that the grass taken with them clogged the teeth, and prevents the heads from falling into the cloath back of them, I must devise some method to clear the teeth, which if I can accomplish, will make it a useful machine, if the heads can be taken off clear of the straw, the labour of thrashing will be saved11—For the farmers own use, perhaps simply thrashing of serving12 the clover in the heads may very well answer the purpose—but if he wants seed for sale, it must be well cleaned—The dust attending the cleaning of Clover-seed is very offensive to the Lunges.

I have heard that the men who work at Clover mills receive double wages in Lancaster.

the points are plates of Steel, they take off the heads with ease, but I found that the grass taken with them clogged the teeth, and prevents the heads from falling into the cloath back of them, I must devise some method to clear the teeth, which if I can accomplish, will make it a useful machine, if the heads can be taken off clear of the straw, the labour of thrashing will be saved11—For the farmers own use, perhaps simply thrashing of serving12 the clover in the heads may very well answer the purpose—but if he wants seed for sale, it must be well cleaned—The dust attending the cleaning of Clover-seed is very offensive to the Lunges.

I have heard that the men who work at Clover mills receive double wages in Lancaster.

In churning13 of Butter by the mill, I find that a quick motion will make the best butter, but instantly the butter is come, it must be gathered very Slow. I see a piece in the news paper advising the boiling of the Cream, this method I tryed and found that it injured the butter, making it curdly, or in small lumps—and the butter took longer time before it came, the reverse of what the author said.14

I have sundry machines in the Mill to aid the farmers labour. Instead of feeding with whole corn, we grind it, which also gives us good small homoney, this I consider more wholesome than when fine to make mush of it.

Four stampers falling close togather in a Morter, beats us excellent Homony. a strong and hearty food, the liquor good for laying in Women &c.15 Various stones for grinding our tools is a great conveniency, yet I have seen some loss by it, the Men are too apt to grind their sythes and axes too thin, and thus soon wear them out.

Grinding my plaster is no saving,16 the few tons used on one farm, may as well be ground elsewhere17 as to have the mill-stones cleaned & picked over again. but if a Machine I have, had a pair of large Bullets the weight of which in pushing them round the Kettle would brake the plaster fine, there would not be much trouble to put in, & take out the plaster when ground, I intend to make tryal as soon as I can purchase a pr 4218 w Balls. I cannot perfectly reconsile to my Idea’s the great benefit of the use of Plaster, and I follow the advice of others whose experiance they says is sufficient proof—I have had good crops of Hay, clover especially where I have used the plaster freely. If a good manure, it is certainly a cheap kind, compared to the cost of purchasing Stable manure.

Saving of labour may not be of any importance in some instances in Virginea, where there are many Negroes, whose time should be filled up in the evenings and in bad weather: such as the shelling of Corn, and this may also be done expediciously by treading out with Horses—but as I have nothing to write for your amusement, so likely to be acceptable as descriptions of Machines—and even in this I have but a small chance of giving any thing new to you. Perhaps you have seen machines for shelling Corn—one was invented several years past & shewn at the Philosophical Society, it was a Cylinder of 20 Inches Diameter about 2 feet long—and studed with Iron points projecting about ¼ of an Inch, this Barrel had one half of it enclosed in a semi circular box with gratings at the bottom—to let the Corn through, I dont remember that there was any pins on the inner side of said Box, the distance of the Cylinder from the box just allowed the corn to enter, & the cob was thrown out on the opposite side, it was proposed that springs should admit the Cylinder to raise to take the largest Ears of Corn,—I have a Machine which I use by a strap from the Drum at the Mill, but which farmers in common drive by a treaddle.

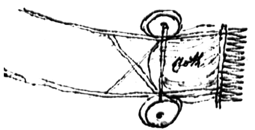

It is 20 Inches Diameter & 2 feet long, a solid piece of White oak. studed with pieces of Iron drove in a small degree in spiral lines; the shape of these pins  projecting ¼ Inch, each angle is about one Inch long—next is a small roller of 2½ Inches Diam:

projecting ¼ Inch, each angle is about one Inch long—next is a small roller of 2½ Inches Diam:  with pins in spiral lines. The small roller is turned by a band from a Pully on the end of the large roller. on the frame below the small roller, is an Iron plate on the inside and Iron pieces19 like those in the large roller drove in an oblike direction

with pins in spiral lines. The small roller is turned by a band from a Pully on the end of the large roller. on the frame below the small roller, is an Iron plate on the inside and Iron pieces19 like those in the large roller drove in an oblike direction  a handle is put to the West end of the little roller to lift it when throwing the Corn between it & the large roller, by the spiral pins the Corn cobs is thrown out at the West end, as fast as the Ears of Corn is thrown in, so fast it is shelled; about 12 Bushels of Ears may with ease be shelled in an hour.20

a handle is put to the West end of the little roller to lift it when throwing the Corn between it & the large roller, by the spiral pins the Corn cobs is thrown out at the West end, as fast as the Ears of Corn is thrown in, so fast it is shelled; about 12 Bushels of Ears may with ease be shelled in an hour.20

For cutting of Straw I have a machine an English Invention, It has a Curved knife on a wheel, the axis of which has a crank to lift up and press down a board to compact the straw which is brought forward by cords round the axis of a ratchet wheel that has the forked rake fastened to the other ends of the Cords—It appears to me that this is an excellent Cutting box, better than most that has come within my knowledge—If I thought it had not come within your notice, I would have given you a Sketch with more particular description of it.21

I remember being present with you When Lord Dunmore shewed us a pr of Elks—I have a male that I have keept in an inclosure upwards of 3 years, his first horns was a single prong about one foot long, he drops His horns in the last week in April, or the first of May yearly, each year they are increased in size, and having heard of a pr of their Horns being full 6 feet long, I am induced to keep this Animal living to see to what length he will acquire horns, as to their having a branch increase for each year, it has no credit with me, & has no better foundation than the yearly increase of a rattle with the Rattle-Viper.

When your Son in Law Mr Randolph was in Philadelphia lately, I was indisposed with a Diarrhaea, or I should have waited on him, and I was told that he intended to come to see me at my farm, It22 would have been highly gratifying to me to see so distinguishd a farmer, on my place, especially the father of Thomas Jefferson.

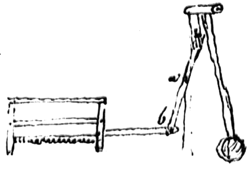

Jany 15th—14. While writing the foregoing, a thought came into my head that I could make a machine that might save labour and also wood, in cutting down Trees &c, and I posponed the finishing of this Scrawl in order to make a Model for tryal, and then to give you a sketch of it After digesting in my mind the several parts of the frame work in order to simplify23 and meet all the different situations it might be placed in for use, I described the principle to 2 or 3 of my ingenous mechanical friends for their opinion of practibility and power of such a machine. and I had but little encouragement from them to proceed—My Dr Sir by this you will find that I am not ashamed to shew any of my weaknesses; that I like to find out my irrors, and I hope that I am always willing to correct them. I write with the desire to give you a few moments of amusement, to give advantage I cannot expect. To proceed, suppose a Pendulum of 10 feet long, the Bob a 56 weight. a slight sketch will illustrate the principle,  To the axis of the Pendulum is a fork 2 feet long, a piece of scantling with a pivot to moove in that fork by the swinging of the Pendulum, its joint to fixture of the frame at (a) which might also be a movable joint to give the Saw a greater or lesser motion, the piece of timber—connected to the Saw has a joint at (b). The Saw keept steady by a frame, which frame may be turned to place the Saw horisontally, in which case the Saw might24 be drawn forward by a weight over a Pully. This Saw being in a frame may be of small size, of coarse will cut with less labour than one large and making a wider cut.

To the axis of the Pendulum is a fork 2 feet long, a piece of scantling with a pivot to moove in that fork by the swinging of the Pendulum, its joint to fixture of the frame at (a) which might also be a movable joint to give the Saw a greater or lesser motion, the piece of timber—connected to the Saw has a joint at (b). The Saw keept steady by a frame, which frame may be turned to place the Saw horisontally, in which case the Saw might24 be drawn forward by a weight over a Pully. This Saw being in a frame may be of small size, of coarse will cut with less labour than one large and making a wider cut.

Speaking of my machine to a friend He thought my Pendulum would moove with great power as he had seen heavy logs that were bored to convey Water at his Mill, drove one into the other by means of a heavy Block suspended by a rope and mooved like a Pendulum to drive one log into the other. I made a model of my Machine of the 4th part of the size I proposed for use, and on tryal of it I found that a machine of such construction would require immence strength about the axis of the Pendulum, its fork, and also in the frame to keep it sufficiently steady in use. And after all it is a question whether any power gained more than could be had by hand labour?

While writing this morning, my Son Rubens seeing the subject of this part of my letter, tells me that a Man living on the commons of Philaa has spent 2 or 3000$ in a plan of mooving Machinery by the power of a Pendulum of very great weight; that he first had two men to swing the Pendulum, and afterward added a fly-wheel with a crank to act on the Pendulum near the center of motion—had made a great quantity of wheels that were to be worked by his Pendulum power, and that many persons had conceived that this person had accomplished a very important discovery. But after all, this Man can do nothing with all his labour and expence—

I have very often in like manner spent my time, labour & expence to no rail advantage, except that of amusing myself very innocently. It brings to my mind a sentiment I meet with last evening in reading the Memoirs of a young Lady, her words are, “happiness is a very common plant, a native of every soil; yet is some skill required in gathering it; for many poisonous weeds look like it, and deceive the unwary to their ruin.” I wish you every happiness that can fall to the lot of man, and believe your Philosophy give you the powers to disreguard the blame sensure, or even applause of the multitude; an approving mind gives a sourse of perfect content.

I once more thank you for your desire to serve me and others by the example you desire me to make.

C W Peale

RC (DLC); with marginal notations by TJ; endorsed by TJ as received 21 Jan. 1814 and so recorded in SJL. PoC (PPAmP: Peale Letterbook); bottom edge torn.

spiring: sprouting, shooting up into a stem or spire (). Peale’s two youngest boys were Benjamin Franklin Peale (1795–1870) and Titian Ramsay Peale (1799–1885) (, 5:xl). The scotch invention for threshing grain described by Peale was the handiwork of Andrew Meikle (). Virginia’s last royal governor, John Murray, 4th Earl of Dunmore, had apparently exhibited a pair of elks to TJ and Peale in Williamsburg in May 1774 (, vol. 2, pt. 1, p. 5n). TJ’s grandson thomas jefferson Randolph boarded with the Peale family, 1808–09 (). The quote happiness is a very common plant … and deceive the unwary to their ruin is from Fragments in Prose and Verse, by Miss Elizabeth Smith, lately deceased. With some account of her Life and Character, by H. M. Bowdler (Boston, 1810), 135.

1. Manuscript: “simce.”

2. In RC to left of this paragraph TJ noted: “horizl ploughing.”

3. Reworked from “Sown.”

4. Manuscript: “is.”

5. In RC to left of this paragraph TJ noted: “hedges.”

6. Manuscript: “off.”

7. Reworked from “them.”

8. Manuscript: “machinees.”

9. In RC to left of this paragraph TJ noted: “threshing.”

10. In RC to left of this paragraph TJ noted: “clover seed.”

11. In RC to left of this paragraph TJ noted: “Gathering clov. seed.”

12. Thus in manuscript. Peale may have intended “or severing.”

13. Manuscript: “churming.”

14. In RC to left of this paragraph TJ noted: “butter.”

15. In RC to left of this paragraph TJ noted: “beating homony.”

16. Manuscript: “saying.”

17. Manuscript: “eslewere.”

18. Reworked from “40.”

19. Manuscript: “pices.”

20. In RC to left of this paragraph TJ noted: “Corn shelling.”

21. In RC to left of this paragraph TJ noted: “cutting straw.”

22. Manuscript: “I.”

23. Reworked from “simply.”

24. Word interlined in place of “must.”

Index Entries

- agriculture; contour plowing search

- agriculture; corn-shelling machines search

- agriculture; fences search

- agriculture; manure as fertilizer search

- agriculture; straw-cutting machine search

- agriculture; threshing machines search

- American Philosophical Society; and corn-shelling machine search

- axes search

- butter; churning search

- cattle; fences for search

- clover; as crop search

- clover; threshing of search

- corn; and contour plowing search

- corn; hominy search

- corn; machine for shelling search

- cotton; manufactures from search

- crops; clover search

- crops; hay search

- Dunmore, John Murray, 4th Earl of; and elk search

- elk search

- fences; in agriculture search

- fences; to separate farms and factories search

- food; butter search

- food; hominy search

- gypsum (plaster of paris); used as fertilizer search

- hay search

- health; diarrhea search

- health; pregnancy and childbirth search

- horses; and plows search

- horses; and threshing machines search

- machines; corn-shelling search

- machines; sawing search

- machines; straw-cutting search

- machines; threshing search

- manufacturing, household; cloth search

- Meikle, Andrew; inventor of threshing machine search

- oxen; used in agriculture search

- Peale, Benjamin Franklin; and machine construction search

- Peale, Charles Willson; and agricultural fences search

- Peale, Charles Willson; and improved saw search

- Peale, Charles Willson; and milling machines search

- Peale, Charles Willson; letters from search

- Peale, Charles Willson; TJ advises on agriculture search

- Peale, Rubens; and pendulums search

- Peale, Titian Ramsay; and machine construction search

- pendulum; innovations of search

- Randolph, Thomas Jefferson (TJ’s grandson; Jane Hollins Nicholas Randolph’s husband); mentioned search

- Randolph, Thomas Mann (1768–1828) (TJ’s son-in-law; Martha Jefferson Randolph’s husband); visits Philadelphia search

- rattlesnake; growth of rattles search

- Roberts, Job; as farmer search

- Roberts, Jonathan; and threshing machine search

- saws; C. W. Peale’s sawing machine search

- scythe search

- Sellers, Nathan; and corn sieve search

- sheep; C. W. Peale considers raising search

- slaves; and labor-saving devices search

- textiles; manufacturing search

- thorn; as agricultural fence search

- thorn; New Castle search

- thorn; Virginia search

- threshing machines search

- tools; axes search

- tools; scythe search

- War of1812; and economy search

- women; hominy for pregnant search

- wool; production of search

![University of Virginia Press [link will open in a new window] University of Virginia Press](/lib/media/rotunda-white-on-blue.png)